Exaud Blog

Blog

Smarter Retail Delivery: From Fixed Routes to Real-Time Decisions

Move beyond fixed routes. See how retailers cut miles and misses with real-time routing, better ETAs, and driver apps.Posted onby ExaudRetail delivery no longer follows a predictable, spreadsheet-based plan. Same-day demand fluctuations, narrow delivery windows, rising costs, traffic disruptions, and store readiness issues can alter schedules by the hour. What once relied on fixed routes and static assumptions now requires dynamic decision-making with adaptive routing, self-learning ETAs, and driver applications that maintain real-time synchronization across existing enterprise systems such as WMS, TMS, POS, ERP, and CRM.

This guide provides a clear, structured overview of how to transition from static logistics planning to real-time operational intelligence. It covers what “smarter routing” means in practice, which data sources are most valuable, how the system architecture integrates, how to validate ROI through a focused 6-8 week pilot, and where Exaud’s expertise accelerates deployment and impact.

What Is Real-Time Delivery Route Optimization?

Real-time delivery route optimization integrates three core components: a routing engine that accounts for operational constraints (such as delivery time windows, vehicle capacity, dwell times, and driver shifts); live data feeds that reflect real-world conditions (including traffic, weather, order readiness, and customer availability); and a driver interface designed to make in-route adjustments intuitive and frictionless.

Machine learning enhances this process by continuously learning from historical and contextual data (for example, adjusting ETAs based on recurring local patterns like Friday evening congestion near shopping areas or longer unloading times at specific locations). The objective is not to deploy “AI for AI’s sake,” but to enable consistent, transparent, and data-driven decisions that improve delivery accuracy and efficiency.

Static vs Real-Time Routing: Impact on OTIF, Miles and Cost per Stop

Static route planning operates under the assumption that tomorrow will resemble yesterday, an assumption that rarely holds true in modern retail. Fixed manifests generated early in the day cannot accommodate late order pickups, cancelled delivery windows, or unexpected traffic disruptions. The results are predictable: inefficient routes, minor delays that miss delivery windows, incorrect sequence of temperature-sensitive goods, increased second delivery attempts, and higher costs per stop.

By contrast, real-time routing maintains the integrity of the morning plan while enabling responsible re-optimization as conditions evolve. This adaptive approach improves On-Time In-Full (OTIF) performance, reduces kilometres driven per delivery, and decreases first-attempt delivery failures, resulting in more reliable, cost-efficient operations.

Data Requirements for Retail Route Optimization

Implementing real-time route optimization does not require perfect data, only the right foundational elements, consistently structured. Orders should include validated addresses with accurate geocodes, realistic service durations, and meaningful delivery windows. Vehicle data must reflect actual capacities (by volume, weight, pallet, or tote), specific constraints (such as refrigeration requirements or license classes), as well as depot rules and shift schedules.

Driver profiles should be mapped to the zones they are familiar with and the vehicles they are certified to operate. Supplementary data feeds, such as live traffic, weather conditions, store readiness (“packed and staged”), and customer availability, help reduce preventable delivery failures. Telemetry data, including vehicle tracking or cold-chain sensor inputs, can be optional at launch but quickly prove valuable within the first month of operation.

Reference Architecture: WMS/TMS, CRM and Driver App Integration

Integration Layer

Connect WMS/ERP/POS/e-commerce and CRM to ingest orders, inventory readiness and customer preferences. Use events (webhooks) or polling to propagate status changes. Consistency beats volume: a few well-defined events outperform hundreds of noisy fields.

Decision Engine (VRP/VRPTW)

The solver respects hard rules (time windows, capacity, shifts, dwell times) and soft priorities (VIPs, must-deliver SKUs, store-first/last). Produce the morning plan in batch; perform intra-day re-optimization when meaningful events arrive.

Real-Time Context & ETA ML

Traffic and weather APIs adjust the near-term picture. Lightweight ML calibrates ETAs from your historical patterns so promises feel accurate, not optimistic.

Driver App & Store Console

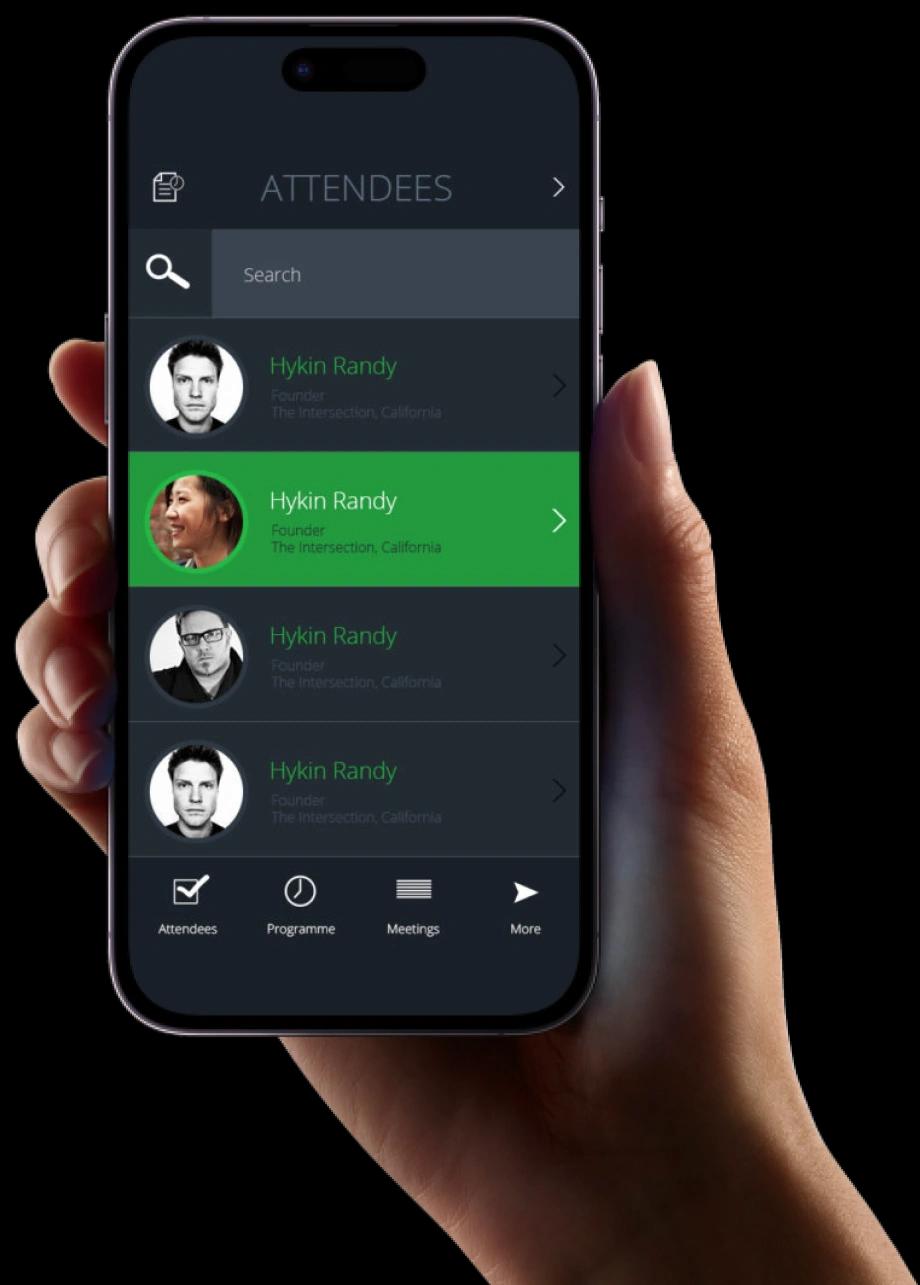

A driver app (offline-first) handles navigation, clear stop sequences, one-tap proof-of-delivery and quick incident capture. Store/ops views confirm readiness, tweak slots and keep comms tight. If the UX is gentle, adoption is fast.

Security & Governance

Role-based access, PII controls and audit trails matter as soon as you re-sequence stops on the fly. Everyone should see what changed, when and why.

6-8 Week Pilot Plan to Validate ROI

Weeks 1-2: Baseline & Data Readiness

Measure today’s OTIF, kilometres per delivery, cost per stop and first-attempt success. Clean addresses, standardise service times/windows and document vehicles/constraints.

Weeks 3-4: Prototype Scenarios

Run as-is vs optimized on a subset of routes and one or two depots. Avoid “perfect world” assumptions. Add simple ETA calibration from local history.

Week 5: Integrations & Field Test

Wire key events (order ready, cancellation, failed delivery). Put the driver app in the hands of 5–10 drivers. Keep the UX minimal and the training practical.

Week 6: Shadow Run

Operate the optimized plan in parallel with the current plan. Compare outcomes and refine soft rules.

Weeks 7-8: Controlled Rollout

Expand by zone/shift. Close the KPI deltas and publish the business case and the scale-up roadmap.

KPIs for Last-Mile Delivery Optimization

When optimizing last-mile operations, it is essential to focus on a concise yet meaningful set of performance indicators, and to analyze them consistently across regions and delivery windows. Start with On-Time In-Full (OTIF), the most reliable measure of how well your planning aligns with operational reality. Next, monitor kilometres per delivery and cost per stop to evaluate overall productivity.

Additionally, track drops per hour and average service time to identify potential on-site inefficiencies, while first-attempt success rate provides insight into how effectively deliveries are completed without the need for repeats. Incorporating estimated emissions per stop supports sustainability initiatives, and customer ratings or Net Promoter Score (NPS) reflect performance from the end-user’s perspective, emphasizing timeliness and communication quality.

Ultimately, when OTIF improves while kilometres per stop and first-attempt failures decline, it indicates genuine operational efficiency, rather than merely shifting bottlenecks further downstream.

Change Management for Drivers and Stores

Real-time routing succeeds only when it aligns with how people work. Sudden, unpredictable changes often lead to confusion and resistance. To ensure adoption, drivers should receive small, well-timed adjustments rather than constant route reshuffles. Provide them with clear route sequences, accurate ETAs, and an intuitive proof-of-delivery (POD) interface. Training sessions should include realistic scenarios such as street closures, delayed pickups, or customers who are temporarily unavailable. At the store level, visibility is equally critical. Teams must understand how their readiness impacts the overall plan. Readiness timestamps promote accountability without assigning blame. Moreover, transparent communication around data privacy, tracking policies, and decision logs helps maintain trust throughout the organization.

Build vs Buy vs Augment for Retail Routing

When it comes to implementing routing capabilities, organizations have three main paths: build, buy, or augment. Out-of-the-box Transportation Management Systems (TMS) are ideal when business constraints are standard and rapid deployment is a priority. Conversely, custom-built solutions are best suited for retailers with unique differentiators, such as multi-depot networks, strict cold-chain requirements, complex prioritization rules, or advanced pricing logic. For many mid-market retailers, the augment approach delivers the optimal balance. This model retains the existing TMS but extends its functionality with tailored modules where they create the most value, for example, a custom optimizer, ETA prediction service, driver application, or SLA monitoring dashboards.

Retail Use Cases: Grocery, Fashion, B2B Replenishment, Cold Chain

Grocery (Same-Day Delivery): Two-hour windows and chilled vehicles demand strict time-window routing and intra-day re-sequencing when traffic spikes before dinner. With store readiness in the loop, late staging stops causing knock-on delays disappear.

Fashion (Click-and-Collect & Returns): Returns can be consolidated with deliveries if the plan understands store calendars and staff levels. OTIF improves while total stops stay stable.

B2B Store Replenishment: Replenishment routes prioritise impending stockouts informed by POS/ERP signals. You drive fewer kilometres with better shelf availability.

Cold Chain: Sensor alerts and maximum door-open times become explicit constraints. Exceptions are flagged early; compliance and customer confidence rise.

How Exaud Helps

We start with a diagnostic and a baseline. In two to three weeks, we typically deliver a prototype route plan connected to your real data. From there, we craft the driver and store apps teams will actually use, wire robust integrations into WMS/ERP/POS/CRM, and add IoT where it makes a measurable difference. Our AI/ML work focuses on decisions you can explain and defend. Finally, we scale with an iterative rollout and the dashboards leadership needs to steer the programme.

FAQs

Is route optimization the same as “AI” in retail delivery?

Both are involved. Optimization produces feasible, efficient routes under real constraints. Machine learning improves ETAs and day-of decisions by learning from your own history.

What integrations matter first for real-time routing (WMS/TMS/CRM)?

Start with WMS/ERP/POS for order status and inventory readiness, CRM for preferences, plus geocoding and traffic/weather. You can expand as KPIs improve.

Do we need perfect data for delivery route optimization?

No. You need consistent addresses with geocodes, realistic service times, and a clear view of vehicle capacities and time windows. Richer signals (readiness, telemetry) come later.

How do drivers handle mid-route changes in real time?

Through a lightweight, offline-first app. They receive a revised sequence, keep navigation, capture POD in one tap, and log incidents in seconds.

How fast can retailers see ROI from real-time route optimization?

A focused 6-8 week pilot on a subset of routes is usually enough to compare as-is versus optimized, quantify gains and plan rollout.

Related Posts

Subscribe for Authentic Insights & Updates

We're not here to fill your inbox with generic tech news. Our newsletter delivers genuine insights from our team, along with the latest company updates.