Exaud Blog

Blog

The Role of Embedded Engineering Services in Modern Product Development

Learn how embedded engineering services power smart, reliable products across industries and drive innovation from concept to launch.Posted onby ExaudModern product development increasingly relies on embedded engineering services to bring smart, connected, and innovative products to life. From smart home gadgets to autonomous vehicles, embedded systems are the “invisible” technology that makes these devices function. Behind every smart thermostat or fitness wearable, it’s not magic at work: it’s embedded software and engineering quietly doing the heavy lifting, connecting hardware with intelligence.

In this article, we’ll explore what embedded engineering services involve, why they are crucial across industries, how they contribute at each stage of product development, and the benefits they offer. We’ll also discuss emerging trends and challenges in the field, as well as when it makes sense to outsource embedded engineering services for your projects.

What Are Embedded Engineering Services?

Embedded engineering services refer to the end-to-end process of designing, developing, and deploying embedded systems - specialized computing systems that perform specific tasks within larger electrical or mechanical systems. These services typically involve integrating hardware and software to create a product with tailored functionality. In practice, this means embedded engineers work on everything from hardware design (microcontrollers, sensors, actuators) to firmware and software development, all the way through system integration and testing.

Unlike general-purpose computing, embedded systems are optimized for dedicated functions, often operating under real-time constraints and resource limitations. They must be highly efficient, reliable, and safe, whether they are controlling a microwave oven or guiding an autonomous vehicle. Embedded engineering service providers ensure that these systems are meticulously architected, coded, and tested to meet specific requirements and standards. This comprehensive approach covers core components of embedded engineering, including hardware design, low-level firmware, application software, and rigorous validation of the final integrated system.

These services are essential across many industries, including consumer electronics, automotive, industrial automation, healthcare, telecommunications, and aerospace. In essence, embedded engineering services provide the technical expertise and development capacity to turn a product concept into a functional embedded system within a device.

Why Embedded Engineering Services Matter Across Industries

Embedded systems are ubiquitous in modern technology, and their engineering drives innovation in multiple sectors. Here are a few key industries where embedded engineering services play a pivotal role:

Automotive Industry

In the automotive sector, embedded software and electronics have become the backbone of innovation. Modern vehicles rely on embedded systems for critical functions like engine control, infotainment, and advanced driver-assistance systems (ADAS). As cars get smarter and more connected, embedded engineering enables features such as collision avoidance, adaptive cruise control, and autonomous driving capabilities. In fact, the automotive industry is undergoing a major transformation powered by embedded software, and the demand for advanced embedded systems has never been higher. From powertrain efficiency to in-car connectivity, automotive manufacturers rely on specialized embedded engineering to design the complex electronic control units and software that enable new features.

Industrial IoT and Automation

Embedded engineering services are equally crucial in industrial settings and the Industrial IoT (IIoT) domain. In manufacturing and automation, embedded systems control machinery, monitor processes, and collect data for predictive maintenance. This leads to improved efficiency and reduced downtime on the factory floor. Embedded controllers and sensors enable smart factories, robotics, and efficient supply chains. More broadly, across energy, agriculture, and other industrial sectors, embedded devices are connecting equipment and processes to the cloud, enabling real-time monitoring and optimization. By leveraging embedded engineering expertise, industrial companies can implement robust IoT solutions that improve operational reliability and safety in environments where failures can be costly.

Consumer Electronics

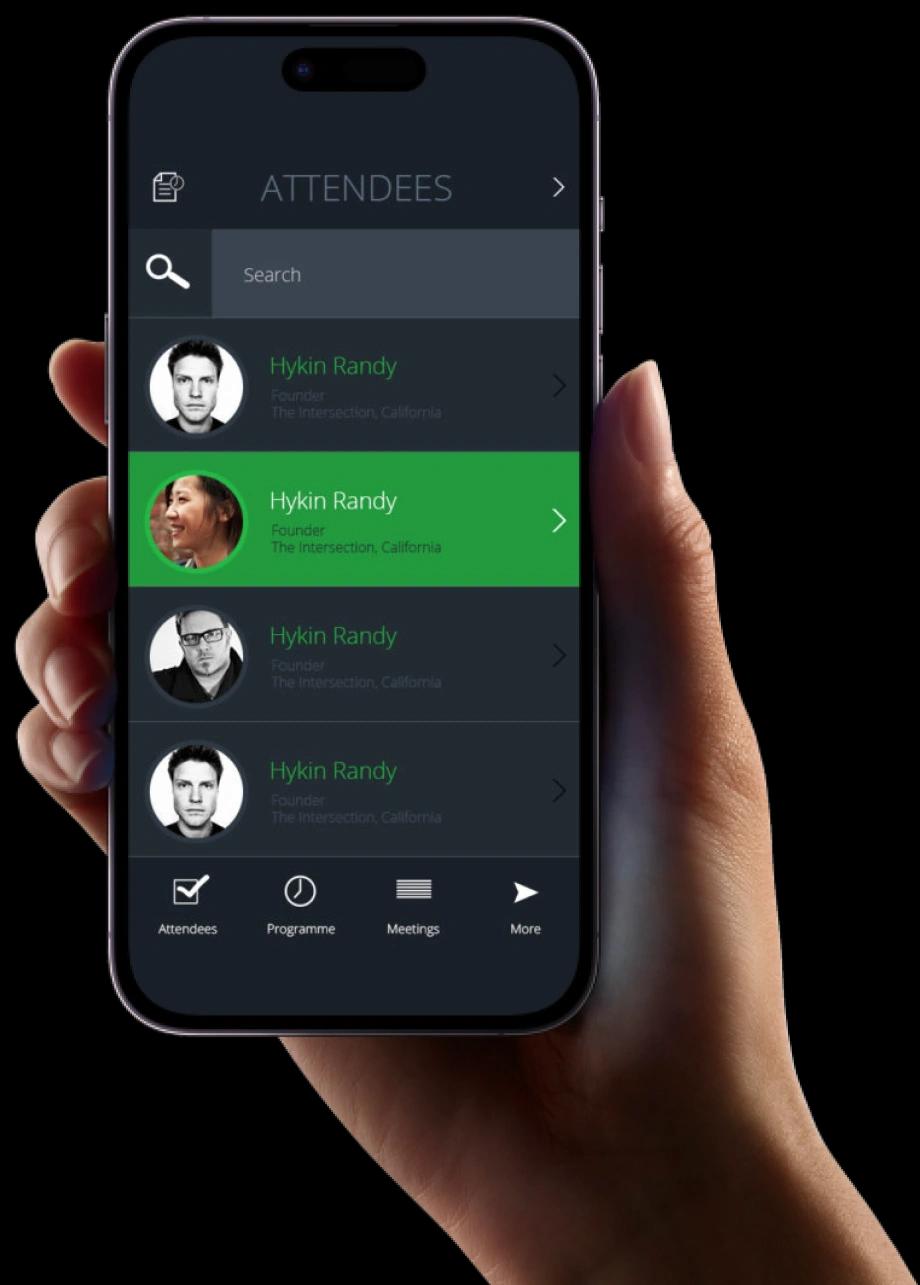

In the consumer electronics realm, embedded systems power the smart devices that people use every day. Smartphones, smart home appliances, wearables, and IoT gadgets all contain embedded computers dedicated to specific tasks. For example, a smart thermostat uses embedded software to learn your schedule and adjust temperatures, and a home security camera uses it to detect motion and stream video. Devices like these utilize embedded software to provide automation and remote control features. Embedded engineering services help consumer tech companies design products that are not only feature-rich and user-friendly but also reliable and efficient within the cost and power constraints of consumer devices. By integrating hardware and software seamlessly, these services ensure that consumer products deliver the intended experience (e.g., instant responsiveness or long battery life) while maintaining safety and compliance standards.

(Other sectors like healthcare, aerospace, and telecommunications also benefit from embedded engineering, from medical devices that must be fail-safe to communications equipment that handles real-time data, underlining the cross-industry importance of these services. Wherever specialized, computerized control is needed in a product, embedded engineers are likely involved).

From Ideation to Production: Support at Every Stage

One of the greatest strengths of engaging embedded engineering services is that they can contribute value at every stage of product development - from the initial idea to mass production and beyond. Let’s break down the role of these services at each key stage:

Ideation and Concept Development

In the concept and ideation phase, embedded engineering experts work with product leaders to assess feasibility and shape the technical vision. This often includes consulting on hardware choices (such as which microcontroller or sensors fit the use case), defining system architecture, and ensuring that the concept can actually be implemented with current technology. Early involvement of experienced embedded engineers can save a company from pursuing impractical ideas by grounding concepts in engineering reality. These services might provide rough prototypes or simulations to validate the idea. By the end of this phase, you have a clearer roadmap of the embedded system requirements, component costs, and potential challenges, which is invaluable for planning. Engaging a skilled team at ideation ensures that when development begins, it’s on solid technical footing.

Prototyping and Development

After the concept is defined, the next stage is building prototypes and iterating on the design. Embedded engineering services shine during prototyping because they bring specialized skills to develop the firmware and hardware rapidly. The team can spin up a proof-of-concept using development boards or custom PCB prototypes, write the necessary software, and integrate the components into a working model. Having an embedded engineering partner accelerates this phase: they know how to streamline development and avoid common pitfalls, leading to faster delivery of a functional prototype. Partnering with a technical outsourcing team for a proof-of-concept can allow your in-house team to focus on business and user aspects while the technical heavy-lifting is handled externally. This speeds up development and ensures the prototype is built with industry best practices in mind. During this stage, embedded engineers will also start iterating on performance, power consumption, and other parameters to meet product requirements.

Testing and Validation

Rigorous testing and validation are critical in embedded product development, and service providers have the expertise and tools to execute them thoroughly. Before a product goes to market, extensive testing ensures the embedded system works under real-world conditions and meets all performance, security, and durability standards. QA for embedded systems can include unit testing of software, hardware-in-the-loop testing (simulate how the device works with other systems), stress testing for environmental conditions (temperature, etc), and compliance testing for industry standards or regulations. By leveraging embedded engineering services, companies gain access to structured testing processes and labs that catch issues early. This stage often uncovers integration bugs or edge cases that need fixing. An experienced embedded team will also help with certifications (for example, ensuring an IoT device meets wireless communications regulations). The result is a reliable product ready for deployment, with the confidence that it has been validated from every angle.

Production and Deployment

When moving to production, embedded engineering services assist in refining the design for manufacturability and scalability. This can mean optimizing code and hardware so that the final product is cost-effective and can be mass-produced without issues. For instance, engineers might fine-tune the firmware to run efficiently on a less expensive microprocessor or adjust the design to improve power consumption, ensuring longer battery life. During production setup, they may help create testing rigs and procedures for quality control on the assembly line, so each unit produced is verified.

Crucially, embedded engineering services don’t stop at product launch – they also contribute to deployment and long-term support. After a device is in the field, there may be software updates, feature enhancements, or security patches required over its lifecycle. Embedded products often remain in use for many years, so planning for ongoing maintenance is important. Service providers typically offer support for troubleshooting, updating firmware (including setting up over-the-air update mechanisms), and scaling the system if new integrations are needed. This long-term engagement ensures the product stays reliable and up-to-date. In short, from hand-holding the transition to manufacturing to sustaining the product through its life, embedded engineering services provide continuity that is hard to achieve alone.

Key Benefits of Embedded Engineering Services

Engaging professional embedded engineering services can bring a range of benefits to a product development effort. Below are some of the key advantages that decision-makers value:

Enhanced Reliability

Products developed with expert embedded engineers tend to be more reliable and safe, thanks to meticulous design and thorough testing. By optimizing systems for their specific function and environment, these services reduce the risk of failures in the field. For example, an embedded service team will ensure the system meets strict safety standards (critical in sectors like automotive or medical) and performs consistently under real-world conditions. The result is higher product quality and trustworthiness.

Improved Efficiency

Embedded engineering services can significantly improve both development efficiency and product performance. With their specialized knowledge, they streamline the development process, avoiding trial-and-error delays. This often leads to faster time-to-market for new products. Moreover, they optimize the software and hardware design so the end product runs leanly, using minimal power, memory, and processing resources for the task. An efficient embedded design translates to benefits such as longer battery life in portable devices and lower hardware costs without compromising functionality.

Scalability and Future-Proofing

A good embedded architecture sets your product up for scalability. This means it’s easier to add new features, support more users/devices, or adapt the product for future variants. Experienced embedded teams will design with modularity and scalability in mind, so your solution can grow or be reused in next-generation products. They also keep an eye on emerging technologies (such as new IoT protocols or AI capabilities) and can incorporate those, ensuring your product stays competitive. In short, embedded engineering services help “future-proof” your product to some extent, accommodating updates and integrations down the line.

Long-Term Support & Maintenance

As noted, products with embedded systems often have long lifecycles, remaining in service for years. One major benefit of having an embedded engineering partner is the ability to provide ongoing support. They can handle maintenance updates, security patches, and upgrades over the product’s lifespan. By designing with maintainability in mind and offering support contracts, these services ensure your product doesn’t become obsolete or vulnerable after a few years. This reduces maintenance costs and headaches for your team. Long-term support from experts means your device can evolve with user needs and stay reliable far into the future.

In sum, leveraging embedded engineering services can lead to a more robust, efficient, and scalable product, while also easing the burden on your in-house teams. Companies can deliver higher quality to their customers and react faster to market changes by having this expertise on board.

Emerging Trends and Challenges in Embedded Engineering

The landscape of embedded systems is continually evolving. New trends are shaping how products are developed, even as engineers grapple with longstanding challenges. Here we outline some prominent trends and key challenges in modern embedded engineering:

Emerging Trends to Watch:

AI and Machine Learning at the Edge: One of the biggest trends is the integration of artificial intelligence into embedded devices. From tiny AI accelerators on microchips to smarter firmware, companies are pushing intelligence closer to where data is generated. This allows real-time decision-making (think cameras that do object recognition on-device, or industrial sensors with built-in anomaly detection) without always relying on the cloud. Additionally, AI is starting to assist engineers in development, for example, using AI tools to generate or optimize code. The growing influence of AI is expected to continue transforming how embedded systems are designed and what they can do.

Connectivity and IoT Expansion: The Internet of Things continues to expand, with billions of connected devices in homes, cities, factories, and beyond. Emerging wireless standards (like 5G, Wi-Fi 6/7) are enabling more devices to communicate seamlessly and at higher speeds. This trend means new products often need to integrate multiple connectivity options and ensure interoperability. The number of connected devices is driving innovation, but also raising the bar for reliability and network security. Manufacturers are increasingly focusing on edge computing - processing data locally on devices - to reduce latency and bandwidth usage, shaping how embedded software is architected.

Open-Source Platforms and Tools: There is a notable shift towards open-source software in embedded development. Modern embedded projects frequently use open-source real-time operating systems (RTOS) like Zephyr or free Linux distributions (Yocto, etc.), as well as community-driven libraries and frameworks. This open-source dominance is growing because it offers flexibility, lower cost, and a broad support community. Similarly, newer programming languages like Rust are gaining traction in the embedded world. For product teams, these trends mean faster development (by reusing existing components) and potentially more secure and up-to-date code, as many contributors help improve these tools continuously.

Challenges to Overcome

Security/Cybersecurity Risks: With greater connectivity comes greater risk. Embedded systems security is a top concern for modern products. A breach or hack can have serious consequences, from safety hazards to data theft. Ensuring robust security in small devices is challenging because of limited computing resources and the need for cost efficiency. Engineers must implement strong measures like encryption and authentication. As embedded devices often form part of critical infrastructure or handle sensitive data, cybersecurity is non-negotiable. Development teams need to stay vigilant and regularly update devices to fix vulnerabilities.

Integration Challenges: Each generation of products tends to be smarter and more feature-rich than the last, which means embedded systems are becoming more complex. Designing a system where hardware, low-level firmware, and high-level software all work together seamlessly isn't easy. Integrating various components can lead to compatibility issues or unexpected behaviors if not expertly managed. Moreover, embedded engineers must optimize within strict resource constraints - limited CPU power, memory, and battery life require careful balancing of trade-offs. This complexity demands advanced expertise and rigorous engineering processes. It’s a challenge for companies to ensure reliability as systems scale up in complexity.

Long-Term Maintenance: Unlike consumer apps that update every week, embedded devices in the field might run for years or even decades. Managing the long lifecycle is a challenge. Hardware can become obsolete, and providing software updates for many years requires commitment. Companies must plan for component end-of-life replacements and ensure they can deliver firmware updates over time. This is especially challenging if the product is deployed in hard-to-reach places (think satellites). Without long-term planning, devices may become insecure or incompatible as technology standards evolve. Embedded engineering services are often crucial here, as they provide the long-term support and planning needed to keep systems running safely throughout their lifetime.

Despite these challenges, the overall trajectory of embedded engineering is exciting. New tools and methodologies (like model-based design, digital twins for testing, and Agile development tailored to hardware) are helping address complexity and improve quality. By staying aware of the challenges and proactively adopting best practices, companies can navigate the risks while riding the wave of innovation.

When to Consider Outsourcing Embedded Engineering Services

For many organizations, a key question is whether to develop embedded capabilities in-house or to outsource to specialized embedded engineering services. Outsourcing can often be a strategic move to accelerate development and reduce costs under the right circumstances. Partnering with an experienced embedded development provider is frequently a smart choice to save money, improve efficiency, and access specialized expertise. Here are scenarios where outsourcing embedded engineering services makes sense:

Lack of In-House Expertise

If your company is not primarily a tech or software company (i.e., your core team doesn’t have embedded software/hardware specialists), outsourcing is “a good way out” for tackling an embedded project. Rather than hiring and training a full in-house embedded team, which can be time-consuming and costly, you can bring in an external team that already has the know-how. This is especially relevant for firms in traditional industries (manufacturing, healthcare, consumer goods) that now need to develop smart connected products.

One-Off or Short-Term Projects

For a short-term project or a one-time product development, outsourcing often provides more flexibility. You don’t have to commit to long-term salaries and infrastructure for an internal team when the project has a finite scope. External engineers can be contracted to deliver the prototype or product, and then the engagement ends. This approach lets you focus your internal resources on core business activities while the vendor handles the development work. It’s a viable way to test new product ideas or handle side projects without diverting your main team.

Tight Time-to-Market Deadlines

If speed is a priority - for example, a startup racing to launch or a business responding to a competitive threat - outsourcing can ramp up development quickly. Established embedded engineering firms have ready teams, frameworks, and experience to hit the ground running. You can also scale the outsourced team size up or down as needed. This makes it possible to get to market faster by leveraging an external pool of talent, without the delays of recruiting and training. Companies with limited time or resources can thus meet market windows by using outsourcing to augment their capacity. The ability to dynamically scale the development effort can be a game-changer when timelines are critical.

Need for Specialized Skills or Compliance Knowledge

Embedded projects sometimes involve niche technologies or strict regulatory requirements (e.g., developing a medical device that meets FDA software standards, or automotive software that complies with AUTOSAR and ISO 26262). If your project requires highly specialized expertise that your team doesn’t possess, outsourcing to a firm that does have that specific experience is wise. You gain immediate access to engineers who understand the domain, which can prevent costly mistakes. Similarly, outsourcing can provide experts who are up-to-date with the latest industry trends and technologies, ensuring that your project benefits from modern best practices.

In all these cases, outsourcing embedded engineering can reduce development risk and often cost. By tapping into a global talent pool and proven development processes, businesses large and small can execute complex embedded projects without overextending themselves. Of course, it’s important to choose the right partner and ensure clear communication of requirements. For many, a hybrid approach works well, keeping strategic core development in-house while outsourcing specific components or tasks to accelerate progress. When done right, outsourcing offers the dual benefits of technical excellence and business agility.

For decision-makers, investing in embedded engineering services means gaining a competitive edge: faster development cycles, access to cutting-edge technology, and confidence that your product will perform as intended in the hands of customers. Whether you’re building the next automotive breakthrough, an industrial IoT platform, or the latest consumer device, having the right embedded expertise is critical to success.

Ready to bring your next product to life with the help of embedded experts? For tailored solutions and support at every step, don’t hesitate to reach out to our team at Exaud: we’re here to help you build it right from the start. Let’s connect and explore how our embedded engineering services can power your product development goals.

Related Posts

Subscribe for Authentic Insights & Updates

We're not here to fill your inbox with generic tech news. Our newsletter delivers genuine insights from our team, along with the latest company updates.